Over time Direct Store Delivery (DSD) suppliers have grown accustomed to managing orders and store inventory somewhat autonomously, using software and technology provided their company. And while this has improved supply chain efficiency, one major challenge with this approach has always been a lack of transparent data sharing between suppliers and the retailers they service.

Without this collaboration on centralized data, both partners are likely missing the ability to view their business more holistically. Many suppliers that have adopted scan-based trading have found that the right 3rd party solution can provide that missing perspective. Scan-based trading (SBT) isn't new, but advancements in technology from leading data management providers is fueling a resurgence in popularity of SBT, and the capabilities needed to optimize inventory throughout the supply chain.

Here's how the new scan-based trading can help suppliers and retailers finally take control of inventory, while growing sales and providing better service to their clients and consumers.

Centralized Management

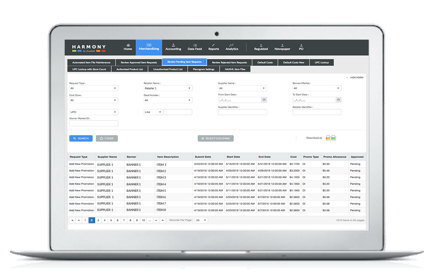

More advanced scan-based trading solutions provide better features and more capabilities than what has previously been available. These new solutions go beyond a focus on payments and allow users to realize the benefits of data synchronization and how it can integrate the fundamental parts of their inventory management system.

More advanced scan-based trading solutions provide better features and more capabilities than what has previously been available. These new solutions go beyond a focus on payments and allow users to realize the benefits of data synchronization and how it can integrate the fundamental parts of their inventory management system.

When you have data all in one place, both suppliers and retailers are able to access all of their accounts within a single centralized platform. Using a web-based solution that stores critical supply chain data in the cloud can provide inventory levels, potential out-of-stocks, and excess inventory from a computer or smartphone.

Electronic Deliveries & Credits

Scan-based trading lets suppliers and retailers experience the efficiency of automated electronic transactions. Paper invoices that detail what was delivered and what was credited out can delay the availability of that key supply chain data in electronic ordering and inventory management systems. In the event that these invoices are misplaced altogether, it can create more headaches trying to reconcile what inventory is actually at store level.

Electronic deliveries and credits can finally turn your inventory management around. By receiving this data via Electronic Data Interchange (EDI), both suppliers and their retailers have the most up-to-date picture of inventory levels by store and by UPC. This data can be updated in real-time to ensure sufficient lead time to make adjustments to future orders.

Better Ordering and Forecasting

Thanks to centralizing data, trading partners have better visibility into inventory information. Suppliers are now able to view retailer point-of-sale (POS) data that is updated on a daily basis. Just as with deliveries and credits, having POS is another key data point in calculating on hand inventory. Because multiple orders are generated per week, it is essential that this data is made available on a daily basis.

This visibility improves supplier order and forecasting accuracy because they don't have to wait a week or more to find out how much of their product has sold. Best-in-class scan-based trading solutions also offer daily invoicing based on retailer POS that not only provides sales reporting, but also ensures that the supplier is paid more quickly after the sale at the register.

Managing the Impact of Shrink on Inventory

Another challenging aspect of inventory control is understanding how much of a supplier's product was lost due to shrink. This can be the result of damages, misplaced or miscounted product, or theft at store level. Shrink may be an unavoidable part of doing business at retail. But with the right solutions in place, scan-based trading can help both suppliers and retailers proactively reduce shrink regardless of who has ownership of it.

Effective shrink management combines the previous three SBT benefits of centralized management, better delivery/credits reporting, and greater access to POS sales; and uses each of these data sets to track shrink at the store/UPC level. No longer does shrink have to be a black hole that hurts category profitability.

The new SBT empowers trading partners to understand the sources of shrink using advanced analytics, and track performance over time. Even shrink settlements can be processed with this same level of granularity, and these adjustments feed directly into the on hand inventory quantities in each store.

More Informed Reporting and Analytics

Ultimately, the greatest benefit of scan-based trading when trying to more effectively manage inventory at retail is the ability to combine and aggregate what were once disparate data sets between suppliers and retailers into a single, centralized reporting and analytics platform. This can include dashboards, scorecards, alert notifications, and even report subscriptions that help automate the oversight of these powerful tools.

Effective analytics and reports are only as good as how easy they are to understand. The best software makes it easy for users to analyze, digest, and take action based on more data-driven assumptions.

Contact us to learn more about iControl's scan-based trading solution.